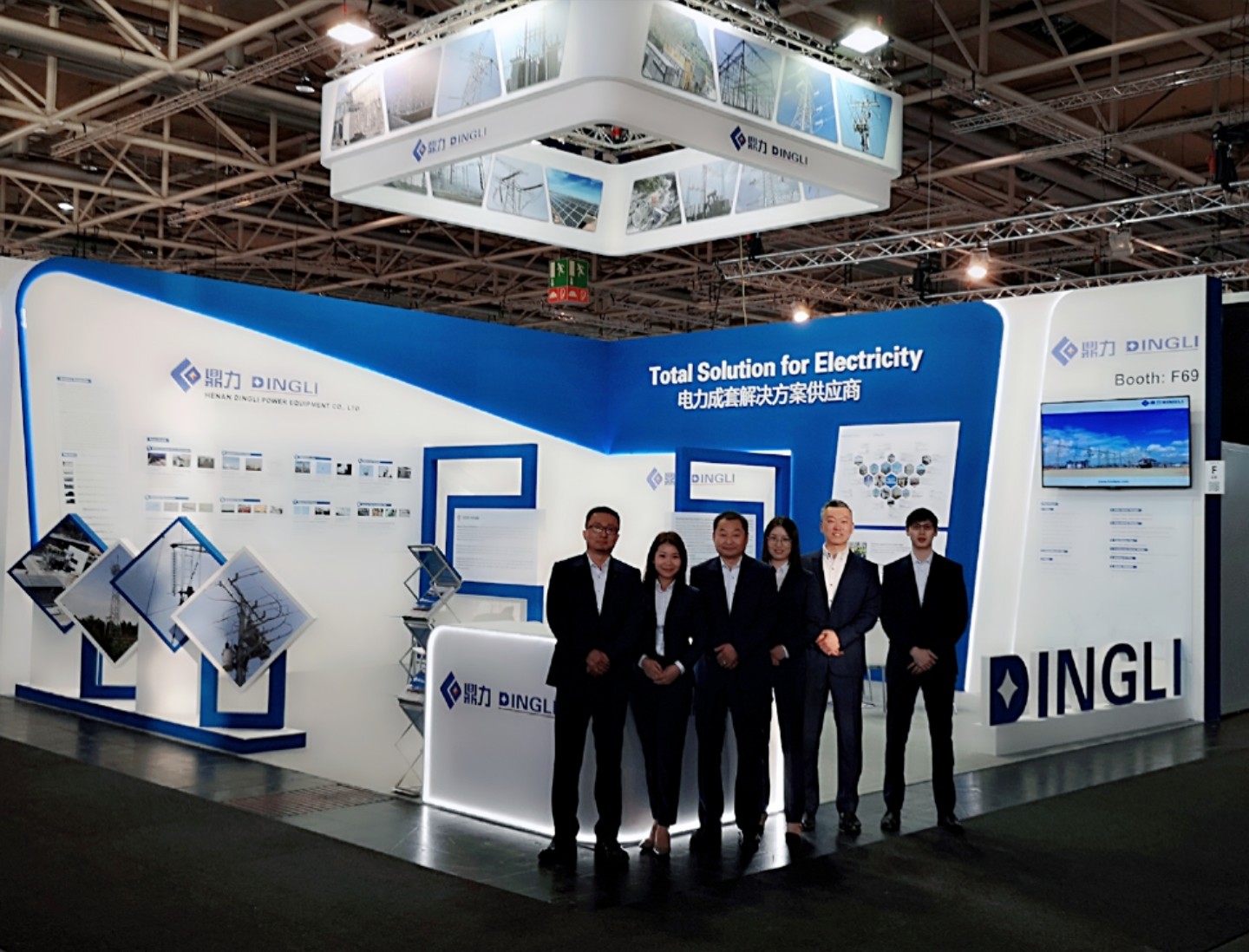

FOCUS ON POWER PACKAGE SOLUTIONS

DINGLI has a complete production and service industry chain covering survey, design,

equipment manufacturing, complete equipment supply, power engineering construction,

operation and maintenance, overhaul and power investment. Our company actively

participates in the construction of power grids and as a high-quality supplier of UHV projects,

we have participated in all UHV construction projects and contributed to the UHV transmission

line business in China.

Service Team

Service

Experienced senior engineers and technical staff keeping on learning can help perform design accurately

and timely and ensure quality, reliability and innovation of products. With the help of the latest advanced

design software of PLS-Pole and AutoCAD, experienced engineers of the Company can design schemes

meeting complex landform and environment, so as to meet various needs of customers.

In the whole pole and tower manufacturing industry, experienced engineers and designers make the Company

be available of designing accurately and timely and ensuring quality, safety and easy construction. On the

basis of an excellent design team, the Company further configures software of PLS-Tower, AutoCAD, BOCAD

and other CAD and updates the software in real time to ensure the software is the latest.

Supported by both domestic engineering company and Quito tower design center, could provide technical

consultant and design service within our scope of work. For Quito tower design center, most of the engineers

are local staffs. The Design is based on ASTM protocols meantime with GB material standard, which will reduce

the weight, and avoid the replacement on the profiles to save the working time.

Project management—Your Dingli Utility project manager oversees all the details necessary to ensure your

project delivers as specified. What’s more, he/she communicates with you every step of the way.

After-Sale Service

With strong technical support capability and on-site service capability, DINGLI has saved

a lot of project costs for customers and won the recognition of customers.

Technical Support

Technical support on pre-sales stage. DINGLI has own survey and engineering company with more than

100 engineers. We have special pre-sales engineer to work with customer at early stage of the project.

Site assistance

Site assistance in Latin American market, so far we have sales and service center in Spain, Chile, Bolivia,

Peru, Ecuador, Senegal, which will make a fast response for customer.

Warehouse and Emergency Supply

Warehouse and emergency supply for spare parts, damage parts and missing parts: DINGLI has built

production line in Quito and warehouse for transmission line and distribution network in Ecuador, Bolivia

and Senegal with common use spare parts.

Design and Consultant

Supported by both domestic engineering company and Quito tower design center, could provide technical

consultant and design service within our scope of work. For Quito tower design center, most of the engineers

are local staffs. The Design is based on ASTM protocols meantime with GB material standard, which will

reduce the weight, and avoid the replacement on the profiles to save the working time.

Professional Packaging Display

Packing Method

Packing Detials

A. Profiles packing methods:

Profiles will be packed by drums. Each drum shall not exceed 2 tons. The profiles below length of 5.8 meters

at least tied 4 times, above length of 5.8 meters at least tied 6 times, to ensure them are not scattered bundle.

Each drum could be adjusted by customers when packing. And there is a plastic filler piece between every

two profiles to avoid being worn.

B. Steel Plate packing methods:

The steel plate ( including warning signs and number plate) will be packed by iron boxes, each box shouldn’t

exceed 2 tons.

There are beams under the box for forklift loading. And each box has lifting holes around the foursquare easy

for lift loading.

C. Bolts packing methods:

Each type of bolts ( including nuts, washers, etc.) will be individually wrapped in woven bags . Each woven bag

should not exceed 30KG, then packed in metal bucket. Each bucket should not exceed 1.5 tons.

D. Identification

Correspondingly, each product has detailed identification from piece to packing box.

E. New packing solution

We also offer a better protect packing solution, named railway frame loading solution.

Techniques:

The products will be fixed as one unit in the container then mounted on the frame, and there are wheels under

the frames. Installing rails in the container, put the frame with products into the container, then fix it.

In this case, we would additionally charge 1500USD/40GP for the cost price of welding frame and rails in the factory.

Remarks: Dingli has applied patent for this packing method in 20th OCT, 2016.